WINE CELLAR DESIGN GUIDE

Vigilant is here to help you build your dream wine storage in any size space, on any budget. Our Wine Cellar Guide outlines top considerations, key construction tips, and best wine storage practices. Whether you are just beginning the process of planning or you are ready to build, our sales and design experts are ready to answer any questions and help you achieve the wine storage solution of your dreams!

TABLE OF CONTENTS

CHOOSING YOUR WINE CELLAR LOCATION

THE IDEAL STORAGE ENVIRONMENT

Once you’ve decided to build a wine cellar, do you know what you need to do to properly store wine so it ages to perfection? Here’s some key information on how to store your precious wine collection.

LIGHT

HEAT

VIBRATION

ODORS

COLD TEMPERATURES

HUMIDITY

Humidity and temperature are equally important in maintaining the best wine storage environment. Corked wine is particularly vulnerable to dry conditions while wine stored in bottles with mechanical screw caps is more protected. Ideal humidity should fall in the 60-65% range at 55° F. Humidity levels above 65% at 55° F can be equally dangerous for wine and wine labels.

DETERMINE THE SIZE OF YOUR CELLAR

WILL YOUR WINE CELLAR BE FOR FUNCTIONAL LONG TERM STORAGE? OR AS A SHOWCASE FOR YOUR WINE?

WHAT TYPES OF WINE WILL YOU BE STORING?

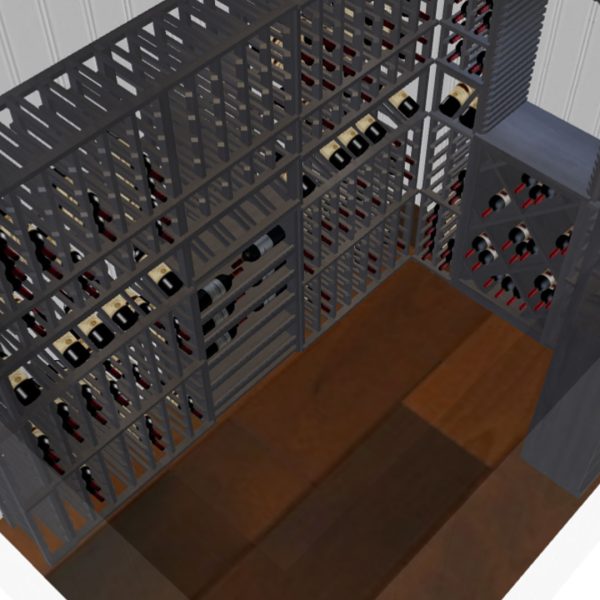

HOW MANY BOTTLES CAN I FIT INTO MY SPACE?

CHOOSING A WINE CELLAR COOLING SYSTEM

COOLING SYSTEMS

Cooling systems are a key component in ensuring your wine is stored in the perfect environment at a consistent, year-round temperature of 55°F with a relative humidity level of 60-65%.

Our complete line of cooling systems use the latest technology and are suitable for every application including ducted, through-wall, and ducted and ductless split systems. With years of experience, we’re happy to recommend the best system for your space.

CHOOSING A VAPOR BARRIER

If traditional batting or rigid foam is to be installed, then you must wrap the walls and ceiling with a 6mm poly vapor barrier so the room is completely sealed.

If the cellar is not in a basement, you will need to install the vapor barrier and insulate the floor as well. Be sure to tape all of the joints of poly with moisture resistant tape and be sure to seal all outlets and lighting fixtures that penetrate the barrier.

INSULATION CONSIDERATIONS

Insulation isolates your wine cellar from exterior elements and helps to maintain a cool, moist environment for your wine. It will keep your passive cellar from becoming too warm and will help to conserve energy for a wine room that is actively cooled by a system.

Non-cement floors with living or crawl spaces below must be insulated with rigid foam, spray-in insulation-preferably closed cell, or traditional fiberglass batting. A vapor barrier must also be applied on these surfaces (excluding a closed cell) as well.

Walls must be insulated with a minimum value of R-19 and ceilings must be insulated with a value of R-30. R-value indicates the ability of the insulation to restrict heat flow — a higher R-value indicates better insulation.

When applying traditional fiberglass batting, make sure to orient the paper or foil barrier toward the warm side of the wine cellar wall. Seal all joints with a foil-backed tape.

CONSTRUCTION MATERIAL

THICKNESSES AND R-VALUES

WINE CELLAR CONSTRUCTION CONSIDERATIONS

FRAMING

Ceilings must be insulated and you may have to insulate the floor, depending on your substrate materials. Once the framing is complete, you will want to run the electrical and plumbing for lighting and your cooling system prior to insulating.

If you are using spray in closed cell foam insulation, this acts as a vapor barrier as well as an insulator so the 6mm poly step in the vapor barrier process is not necessary.

ELECTRICAL

Light switches with dimmers should be placed near the wine cellar door and should control all the lighting in the wine cellar.

Switches with timers or motion detectors are a nice feature that can turn the lights off for you when your hands are full.

This is the time to start thinking about what kind of lighting fixtures you would like and to have the wires run for them. Consider sconces, chandeliers, recessed lighting, can lighting and track lighting.

CHOOSING YOUR MATERIALS

FLOORING

TILE & STONEWORK

HARDWOOD

CEILINGS

Vaulted ceilings and wood ceilings are other optional design elements that can add a unique look to your finished wine cellar. Both tongue & groove and bead board are great options for wood ceilings and can be finished to match your wine racking and wine cellar elements.

WALLS

A moisture-resistant drywall/plywood material is fine for walls and ceilings. We recommend 1/2″ moisture-resistant gypsum wallboard or green board as the most common and cost-effective wall material. This wall board must be painted with moisture-resistant paint.

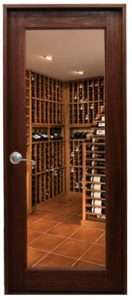

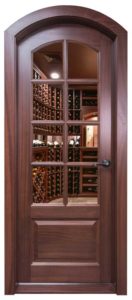

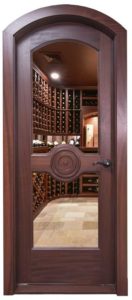

CHOOSING YOUR WINE CELLAR DOOR

Your wine cellar entry door is the first chance to make a first impression. It should be both functional and beautiful. Because the wine cellar is a conditioned space, you want to ensure that the entry door is an exterior grade with weather stripping for a tight seal. In the case of glass doors, make sure the wine cellar door includes high R-Value glass panels. Our Classic and Value Classic doors are the perfect solution.

FULL GLASS DOORS

TUSCAN GLASS DOORS

RUSTIC WOOD DOORS

PROVINCIAL GLASS DOORS

Before ordering your door you must determine its swing; in or out, and left or right. It is preferable to have your door swing into the wine cellar, making sure that its swing path does not interfere with your wine racks.

The positive pressure in a conditioned wine room will push the in-swinging door against the jam and weather stripping, creating a superior seal. When choosing a door with a glass panel, make sure that the panel is dual-paned, insulated glass. The higher the R-value, the better.

CHOOSING YOUR RACKING

WHAT IS A MODULAR WINE SYSTEM?

STAINS & FINISHES

On their own, wooden wine racks are already beautiful. Unfinished mahogany, for example, will reveal its unique quality as it ages over time. But its beauty can be further enhanced when a stain is applied. Generally, wine rack stains come in a wide array of options.

CHOOSING YOUR LIGHTING

The lighting in your wine cellar should be both functional and decorative and should provide ample light for reading wine labels without exposing your wine to excessive heat and ultraviolet light. Putting all of your lighting on wall switches with dimmers will give you the flexibility to raise and lower light levels for the appropriate task. Switch timers or motion detectors are a great feature and will prevent the lights from being left on inadvertently.

Recessed ceiling lights are the best solution for wine cellar lighting. They are unobtrusive, and their specialized fixtures allow you to aim the light to areas where it is most needed.

Track lighting can be used as an alternative or in addition to recessed cans. Track lights are flexible and provide good light.